The DIXIT Project

Distributed information technology for a strategic multiobjective process control

1996-1998 / ESPRIT IV 22130

Better automation is a key aspect for improving industrial competitiveness. Intelligent automation can play a major role in this. However, intelligent control systems are very expensive to build and don’t usually cover all control layers. These costs can be reduced by building generic software components aimed at addressing different types of problems at different control layers, supported and integrated by a flexible architecture, and the definition of a methodology. This was the commitment of the DIXIT project partners.

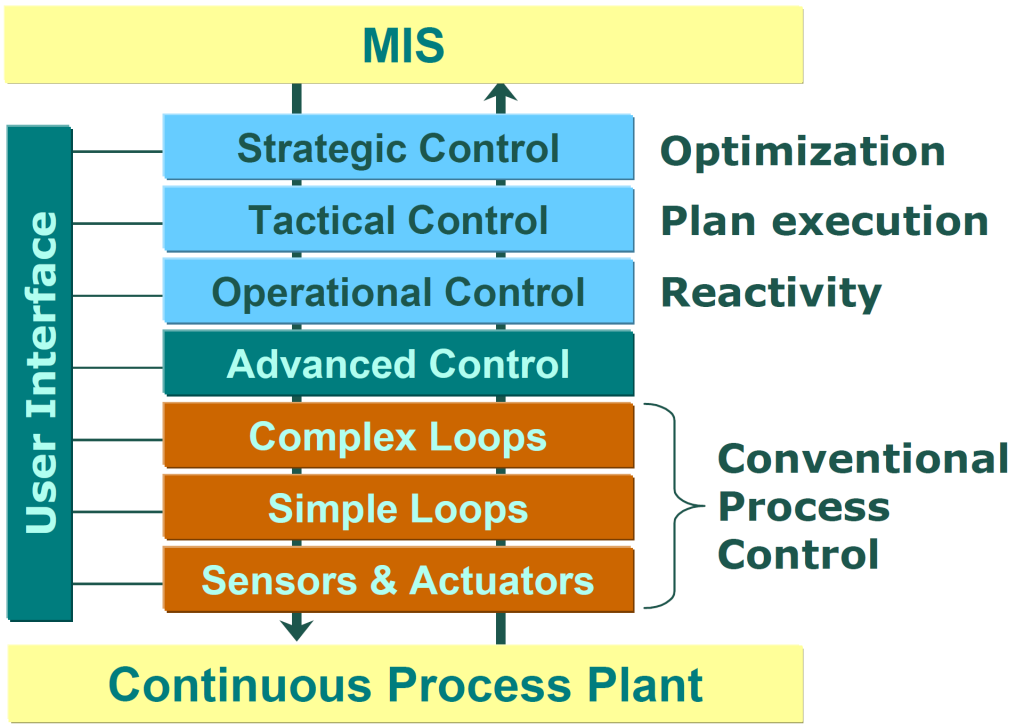

The structure of most distributed control systems is hierarchical and multilayered, similar to a pyramid, where abstraction as well as control mechanisms complexity increases in higher layers. DIXIT dealt with problems and situations included in the intelligent control layers; operational, tactical and strategic. In particular, it focused on the strategic level, especially on environmental, safety and maintenance aspects considering them together with other global objectives of the plant, such as production, quality, etc. All these objectives constitute a constraint network where priorities and weights have to be assigned depending on the situation.

From the user point of view, a DIXIT application helps the plant staff in deciding and acting promptly and uniquely when an abnormal situation -e.g. an emergency- is detected. This increases plant safety. In addition, it facilitates the access and integration of large amounts of information and complex data. Finally, the prevention of these emergencies is also an important benefit from the use of a DIXIT application.

From the technical point of view, the DIXIT final product was a toolbox of integrable software modules: user interface components, problem solving components and architectural components. The problem solving modules performed tasks such as failure detection, diagnosis, monitoring, tactic creation and recommendation, sensor validation, forecasting, alarm and emergencies handling, prevention, optimization, etc. The technologies used were rule-based systems, neural networks, fuzzy logic, mathematical optimization techniques, etc. In order to support the other modules and the distribution features, the DIXIT architectural components combined the blackboard paradigm (already proven as a successful approach for intelligent applications) with agent-based, distributed system paradigms.

The project produced software components, methodology and an engineering environment aimed at preventing and solving control problems at different intelligent control layers (operational, tactical and strategic). The strategic situations to deal with focus on safety, environmental and maintenance issues.

The consortium was formed by five technical developer organisations (IIC, acting as co-ordinator, RH&H, DaCapo and UPM-DISAM and Euristic Systemes) and two users (Repsol Quimica and Lafarge Ciments). Four European countries were represented in the consortium.

Reference

Plantwide Risk Management Using Distributed Objects, R. Sanz, M. Segarra, A. De Antonio, I. Alarcón, F. Matía, and A. Jimenez, IFAC SAFEPROCESS, vol. 33, no. 11, pp. 699–703, 2000.